Product Overview

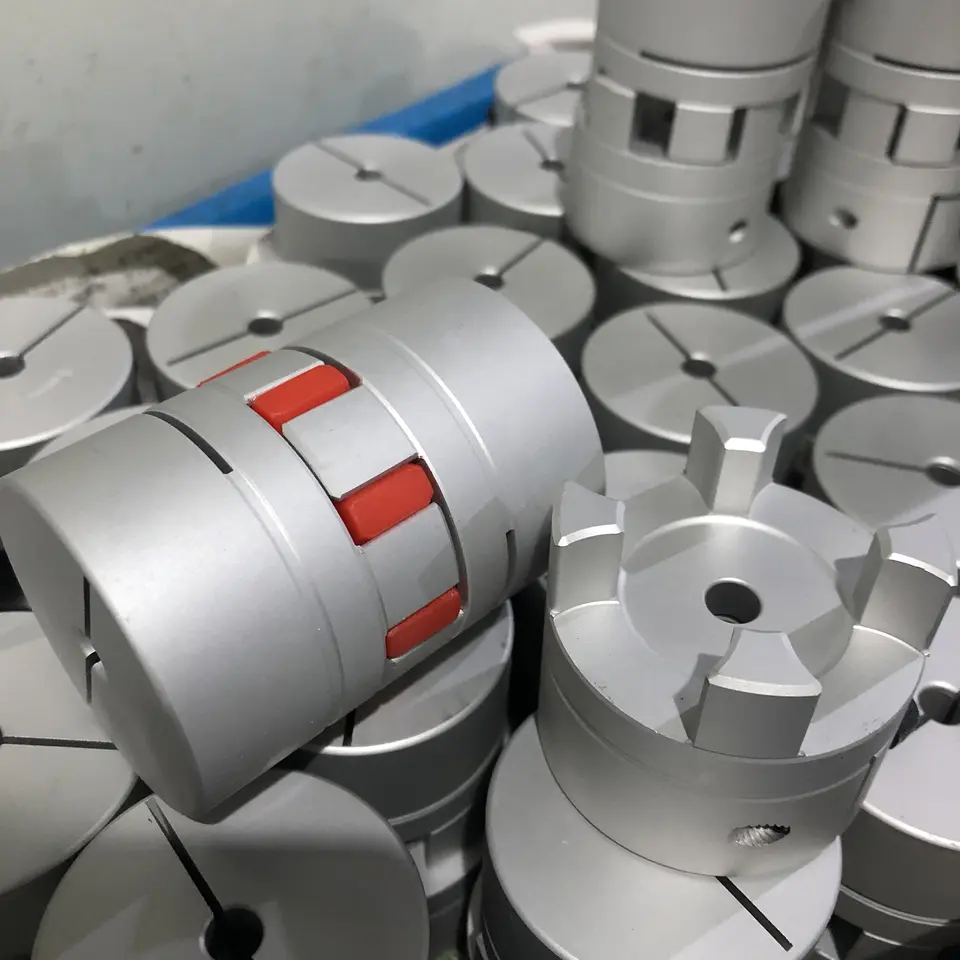

This jaw coupling is a flexible coupling that connects two shafts together for transmitting torque while damping vibrations. It is commonly used in various industrial applications due to its versatility and reliability.

Features of Jaw Coupling

- High torque capacity

- Easy installation and maintenance

- Excellent misalignment compensation

- Dampens vibrations and reduces noise

- Long service life

Applications of Jaw Coupling

Jaw coupling is suitable for applications that require high torque transmission and vibration damping. Some of its key advantages include:

- Perfect for use in pumps and compressors

- Ideal for conveyor systems

- Suitable for power transmission equipment

- Used in various industrial machinery

- Commonly found in packaging and printing machines

Working Principle of Jaw Coupling

The jaw coupling works by transmitting torque from one shaft to another through elastomeric spiders that are placed between the two hubs. These spiders allow for angular misalignment and axial motion while maintaining a strong connection between the shafts.

How to Choose the Right Jaw Coupling

- Consider the torque requirements of the application

- Take into account the shaft sizes and speed of rotation

- Determine the amount of misalignment that needs to be accommodated

- Choose the appropriate material based on environmental conditions

- Ensure proper fit and alignment during installation

Maintenance of Jaw Coupling

Proper maintenance of jaw coupling is essential to ensure its optimal performance and longevity. Regular inspection for wear and tear, lubrication of moving parts, and alignment checks are recommended to prevent breakdowns and costly repairs.

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated team of designers and researchers for over 16 years, we offer customized products to meet the unique needs of our global customers. Our commitment to quality is reflected in our comprehensive quality testing system and CE and TUV certifications. HZPT is known for providing top-notch service, high product quality, and competitive prices. We offer a wide range of coupling products for various industrial applications, making us the best choice for your needs. Contact us today to discuss your requirements and experience the HZPT difference.