Product Overview

This jaw coupling is a flexible coupling that is commonly used to transmit power between two shafts. It is known for its versatility and ability to compensate for shaft misalignment.

Features of Jaw Coupling

- Flexible and torsionally rigid design

- Easy installation and maintenance

- High torque capacity

- Resistant to oil, dirt, and moisture

- Compact size and lightweight

Applications of Jaw Coupling

Jaw coupling is suitable for various applications due to its advantages:

- Used in pumps, compressors, and conveyors

- Ideal for industrial machinery and automation equipment

- Effective in power transmission systems

- Provides vibration damping and shock absorption

- Ensures smooth and reliable operation

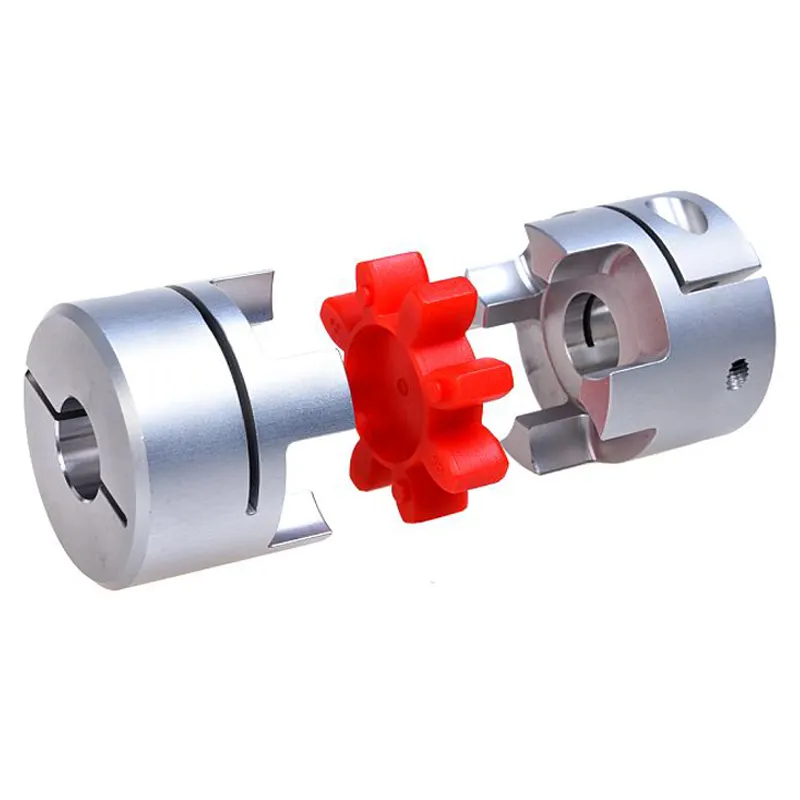

Working Principle of Jaw Coupling

The jaw coupling transmits torque by connecting two hubs with an elastomeric spider insert. When the hubs rotate, the spider compresses and expands to compensate for misalignment and dampen vibrations.

Choosing the Right Jaw Coupling

- Consider shaft sizes and speed requirements

- Check for misalignment and angular offset

- Assess torque capacity and operating conditions

- Select material based on environmental factors

- Ensure proper fit and alignment during installation

Maintenance of Jaw Coupling

Regular maintenance of jaw coupling is essential to ensure optimal performance and longevity. Proper lubrication, inspection for wear and tear, and alignment checks are crucial to prevent unexpected failures and downtime.

About HZPT

Established in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated team of designers and engineers for 16 years, we offer customized solutions to meet global customer requirements. Our products undergo rigorous quality testing and hold CE and TUV certifications. We are committed to customer satisfaction, providing top-notch services, high product quality, and competitive prices.

Our product range includes a variety of couplings such as radial elastic couplings, tire couplings, universal couplings, gear couplings, and more. HZPT’s philosophy emphasizes quality for survival and reputation for development. With high quality, low prices, and a wide range of product models, we are your best choice for jaw couplings. We look forward to collaborating with you for successful business relationships worldwide.