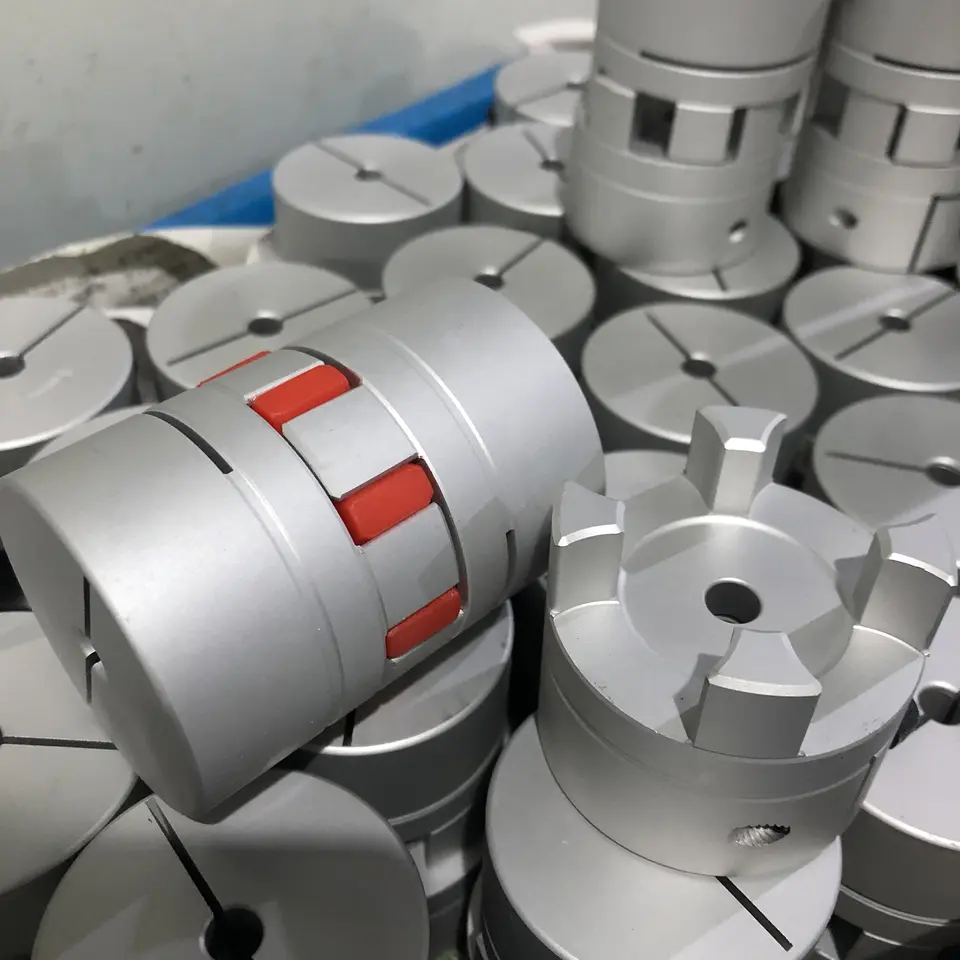

Product Overview

This jaw coupling is a flexible coupling that is commonly used to connect two shafts together. It features a simple design and is known for its high torque capacity and vibration dampening properties.

Key Features

- Simple and reliable design

- High torque capacity

- Excellent vibration dampening properties

- Easy to install and maintain

- Wide range of sizes and materials available

Applications

The jaw coupling is ideal for applications that require high torque transmission and flexibility. It is commonly used in industries such as manufacturing, mining, and automotive. The advantages of using a jaw coupling include:

- High torque capacity

- Compensation for shaft misalignment

- Reduced vibration and noise

- Easy installation and maintenance

- Long service life

Working Principle

The jaw coupling works by transmitting torque from one shaft to another through the elastomeric spider located between the two hubs. The spider absorbs shocks and vibrations, protecting the connected equipment from damage.

Choosing the Right Jaw Coupling

- Consider the torque requirements of your application

- Determine the amount of misalignment that needs to be accommodated

- Choose the appropriate size and material for the coupling

- Check the operating temperature range

- Ensure proper installation and alignment

Maintenance of Jaw Coupling

Regular maintenance of the jaw coupling is essential to ensure optimal performance and prevent premature wear and failure. It is important to regularly inspect the coupling for signs of wear, misalignment, or damage, and replace any worn components as needed.

About HZPT

Established in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team of 16 years, we offer custom products tailored to the needs of global customers. Our products are CE and TUV certified, reflecting our commitment to quality and customer satisfaction. HZPT is known for providing top-notch service, high product quality, and competitive prices. We look forward to establishing successful business relationships with new customers worldwide.