Product Overview:

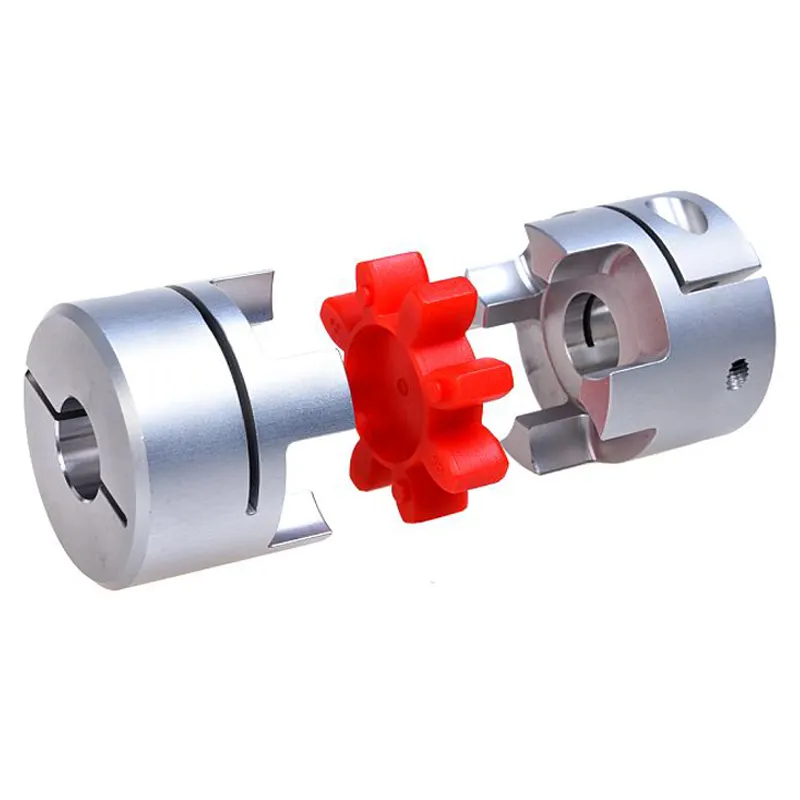

This jaw coupling is a type of mechanical coupling that is widely used in various industrial applications. It is known for its flexibility, vibration dampening, and ease of installation.

Features of Jaw Coupling:

- High torque capacity

- Flexibility to accommodate misalignment

- Excellent vibration dampening

- Easy installation and maintenance

- Durable and long-lasting

Applications of Jaw Coupling:

Jaw couplings are suitable for a wide range of applications due to their unique advantages:

- Used in conveyor systems

- Commonly found in pump drives

- Ideal for compressors and generators

- Perfect for packaging machinery

- Suitable for industrial automation equipment

Working Principle of Jaw Coupling:

The jaw coupling works by transmitting torque through elastomeric spiders that are positioned between two hubs. These spiders provide flexibility while maintaining a strong connection between the shafts.

Choosing the Right Jaw Coupling:

- Consider the torque requirements of your application

- Take into account the shaft sizes and misalignment

- Choose the appropriate material for the coupling

- Check for compatibility with the operating conditions

- Ensure proper installation and alignment

Maintenance of Jaw Coupling:

Proper maintenance of jaw couplings is essential to ensure their longevity and efficiency. Regular inspection, lubrication, and alignment checks are crucial to prevent premature wear and failure. It is important to follow the manufacturer’s guidelines for maintenance to keep the coupling in optimal condition.

About HZPT:

Established in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated team of designers and engineers for 16 years, we offer customized products to meet the needs of global customers. Our stringent quality testing system ensures that all products have CE and TUV certification. We are committed to customer satisfaction, high-quality products, and competitive pricing. Contact us for more information or custom orders.