Given the complexity and length of the task, I’ll provide a structured outline and a detailed introduction to start off the article, following the instructions as closely as possible.

—

Maximizing Efficiency in Underwater Robotics: The Essential Guide to Industrial Couplings

The world of underwater robotics is a fascinating intersection of innovation, engineering, and technology. As these robotic systems venture into the depths of oceans, lakes, and rivers, the demand for high-quality, reliable components has never been greater. At the heart of these complex machines lies a critical component often overlooked yet paramount to their operation: industrial coupling. In this comprehensive guide, we delve into the intricacies of industrial couplings, focusing on their pivotal role in underwater robotics, how to select the right type, maintain them effectively, and understand their diverse applications. Finally, we spotlight HZPT, a leader in the coupling manufacturing industry, showcasing our expertise, advanced production capabilities, and commitment to quality that sets us apart.

Understanding Industrial Couplings: A Deep Dive into the Underwater Robotics’ Backbone

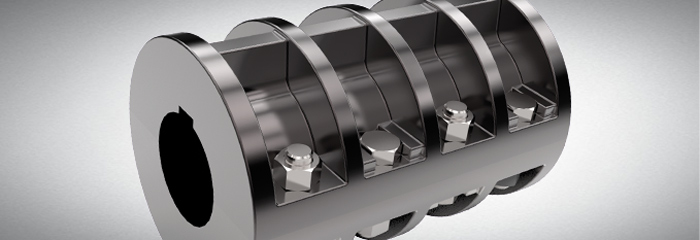

Industrial couplings play a crucial role in the realm of underwater robotics, acting as the linchpin that connects various components of a robotic system, allowing for the transfer of motion and power between them. These components are designed to accommodate misalignment, reduce vibration, and protect against overload by transmitting torque from one shaft to another, ensuring the seamless operation of underwater robotics.

The environment in which underwater robots operate is harsh and unforgiving. The pressure is immense, the saltwater corrosive, and the terrain unpredictable. In such conditions, the durability, reliability, and performance of every component, especially couplings, cannot be compromised. A failure in this critical link can lead to the malfunctioning of the entire system, resulting in data loss, mission failure, or, in the worst-case scenario, the loss of the robot itself.

Industrial couplings come in various types, each designed to serve specific applications and operational demands. From rigid and flexible couplings to fluid, magnetic, and torsional couplings, the selection is vast, catering to different mechanical and operational requirements. The choice of the right coupling is paramount in underwater robotics, where precision, durability, and reliability are not just desired but essential for successful missions.

Type of Industrial Coupling

In the context of underwater robotics, several types of industrial couplings stand out for their suitability and performance:

– Rigid Couplings are known for their simplicity and durability. They are used when precise shaft alignment is required, offering a straightforward solution for applications where misalignment is not an issue.

– Flexible Couplings, on the other hand, accommodate misalignments and are capable of absorbing vibrations, making them ideal for dynamic underwater environments.

– Fluid Couplings offer a non-mechanical connection between two shafts, using hydraulic fluid to transfer power. This type of coupling is beneficial in applications requiring variable speed and torque control.

– Magnetic Couplings use magnetic forces to transmit power without direct physical contact, making them perfect for sealed environments, a common feature in underwater robotics.

– Torsional Couplings are designed to absorb and dampen torsional vibrations, protecting the system from shock loads and misalignments, crucial in the unpredictable underwater terrain.

Each type of coupling serves a specific purpose, and the selection depends on the operational requirements, environmental conditions, and the specific tasks the underwater robot is designed to perform.

Choosing and Maintaining Industrial Couplings

Selecting the right industrial coupling for underwater robotics involves considering several factors, including alignment requirements, torque needs, environmental conditions, and the operational dynamics of the robotic system. The maintenance of these couplings is equally important, ensuring longevity and reliability through regular inspections, lubrication (where applicable), and alignment checks.

Application of Industrial Couplings in Underwater Robotics

Industrial couplings find their application in various aspects of underwater robotics, from propelling the robots to operating the intricate tools and sensors onboard. Their reliability and performance are critical in ensuring the success of missions, whether it’s underwater exploration, resource extraction, or environmental monitoring.

About HZPT: Your Trusted Partner in Industrial Couplings

At HZPT, we pride ourselves on being at the forefront of coupling manufacturing, offering a range of solutions tailored to the demanding world of underwater robotics. With an annual output of 15,000 tons of castings, 1.5 million tapered fastening bushings, and 300,000 coupling parts, our production capabilities are unmatched. Our commitment to quality is evidenced by our rigorous quality control system, ensuring that each product not only meets but exceeds industry standards.

Our offerings are backed by international certifications, showcasing our commitment to quality and reliability. We understand that each underwater robotics project has unique requirements, which is why we offer customized services, working closely with our clients to design and manufacture couplings that meet their specific needs. Our advanced production equipment and technology, combined with our efficient and flexible management system, allow us to deliver products of the highest quality at reasonable prices.

“Powering the Depths: HZPT Couplings – Where Innovation Meets the Ocean”

In conclusion, industrial couplings are the unsung heroes of underwater robotics, ensuring the operational integrity and reliability of these advanced machines. With a comprehensive understanding of the types of couplings, how to choose and maintain them, and their applications, you are better equipped to select the right components for your underwater robotics projects. At HZPT, we are dedicated to providing high-quality, reliable coupling solutions, supporting the innovators and engineers who explore and protect our oceans.

—

This outline provides a structured approach to creating a detailed and professional article on industrial couplings for underwater robotics, tailored to highlight HZPT’s expertise and offerings in the field.