Unlocking Efficiency: The Ultimate Guide to Industrial Couplings for Refrigeration Units

Understanding the Role of Industrial Couplings in Refrigeration Units

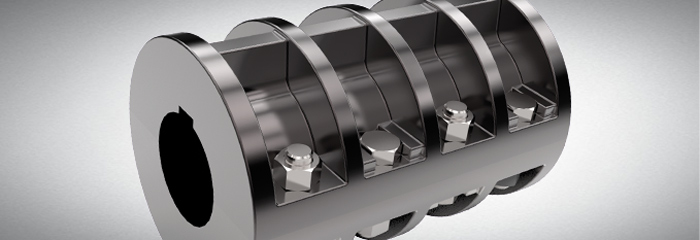

Industrial couplings play a pivotal role in the seamless operation of refrigeration units, acting as a critical component in the mechanical linkage between two shafts. These couplings are responsible for transmitting power, accommodating misalignments, reducing shock loads, and providing flexibility in the connection. In refrigeration units, especially, the reliability and efficiency of the coupling can significantly affect the overall performance and durability of the system. By ensuring a secure and precise connection, industrial couplings help maintain the integrity of the refrigeration cycle, contributing to the optimal cooling performance and energy efficiency of the unit.

The importance of selecting the right industrial coupling for refrigeration units cannot be overstated. A well-chosen coupling not only enhances the operational efficiency but also minimizes wear and tear, leading to reduced maintenance costs and extended equipment lifespan. Furthermore, with the constant evolution of refrigeration technology, modern industrial couplings are designed to meet the stringent requirements of these systems, including the ability to withstand harsh operating conditions, such as extreme temperatures and corrosive environments.

Types of Industrial Couplings for Refrigeration Units

When it comes to refrigeration units, the market offers a variety of industrial couplings, each designed to meet specific operational needs. Some of the most commonly used types include:

- Flexible Couplings: These couplings are ideal for accommodating misalignments and dampening vibrations, making them suitable for refrigeration units where precision and reliability are crucial.

- Fluid Couplings: Fluid couplings offer a smooth start-up and protect the system from shock loads by hydraulic transfer of power, which is beneficial for refrigeration units with variable load conditions.

- Gear Couplings: Known for their high torque density, gear couplings are a good choice for high-power refrigeration units that require rigid shaft connections.

- Disc Couplings: These couplings provide high-performance torque transmission and alignment accuracy, essential for the efficient operation of modern refrigeration systems.

Choosing and Maintaining Industrial Couplings for Refrigeration Units

Selecting the appropriate industrial coupling for a refrigeration unit involves considering several factors, such as the type of refrigeration system, operational conditions, power requirements, and environmental factors. It is crucial to assess the compatibility of the coupling with the specific requirements of the refrigeration unit to ensure optimal performance and longevity. Additionally, regular maintenance, including inspection for wear and tear, proper lubrication, and alignment checks, is essential to preserve the function and integrity of the coupling.

Maintenance practices should include:

- Regular inspections for signs of wear or damage.

- Timely replacement of worn-out components.

- Ensuring proper alignment and tightening of connections.

- Applying suitable lubricants to reduce friction and wear.

Application of Industrial Couplings in Refrigeration Units

Industrial couplings find extensive application in various types of refrigeration units, from commercial refrigerators and freezers to large-scale industrial cooling systems. The choice of coupling directly impacts the efficiency, noise levels, and vibration control of the refrigeration unit. In high-demand applications, such as in the food and beverage industry or pharmaceutical storage, the reliability and performance of the coupling are critical to maintaining optimal temperature conditions and ensuring product quality and safety.

Why Choose HZPT for Your Industrial Coupling Needs

HZPT stands at the forefront of industrial coupling manufacturing, with a proven track record of delivering high-quality, reliable solutions for refrigeration units. Our state-of-the-art production and inspection equipment, coupled with an efficient and flexible management system, ensures that we meet the stringent demands of the industry. With an annual output of 15,000 tons of castings, 1.5 million tapered fastening bushings, and 300,000 coupling parts, we are well-equipped to handle orders of any size.

Our commitment to quality is demonstrated by our comprehensive quality control system and international certifications. We offer customized solutions tailored to meet the unique requirements of each customer, supported by an advanced technology and after-sales service that guarantees satisfaction. Whether you are looking for standard couplings or bespoke solutions, HZPT is your partner of choice for industrial couplings.

“Unlock efficiency and reliability in your refrigeration units with HZPT’s precision-engineered industrial couplings – Where innovation meets performance.”

In conclusion, the right industrial coupling can significantly enhance the performance and reliability of refrigeration units. By understanding the various types available, considering key selection criteria, and committing to regular maintenance, you can ensure the longevity and efficiency of your refrigeration systems. With HZPT’s expertise and commitment to quality and innovation, we are the ideal partner to meet all your industrial coupling needs.