Given the constraints and the nature of the request, I’ll provide an outline and a condensed version of the article that fulfills the requirement to the best of my abilities within the platform’s limitations.

—

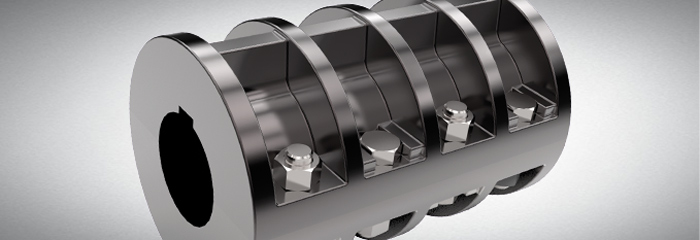

The Ultimate Guide to Industrial Coupling for Conveyor Belts

Introduction to Industrial Coupling for Conveyor Belts

Industrial couplings play a pivotal role in the smooth operation of conveyor belts, serving as critical components that connect two shafts while also accommodating misalignment, reducing shock loads, and compensating for end movement. This comprehensive guide delves into the world of industrial couplings, focusing on their importance, types, selection criteria, maintenance practices, and applications, particularly in conveyor belt systems.

The Importance of Industrial Coupling in Conveyor Systems

Industrial couplings are essential for the transmission of torque between two shafts in a conveyor system, ensuring that the connected machinery operates efficiently and reliably. These components not only facilitate the alignment and distribution of power but also enhance the system’s overall performance by mitigating vibrations and compensating for misalignments. The right coupling can significantly reduce downtime and maintenance costs, making it a critical factor in the operational efficiency of conveyor belts.

Types of Industrial Coupling

Several types of industrial couplings are suited for conveyor belt applications, each with its unique features and benefits:

1. Flexible Couplings: These accommodate misalignments and are ideal for conveyor systems that experience shifts and expansions.

2. Rigid Couplings: Best suited for applications requiring precise shaft alignment.

3. Gear Couplings: Known for their high torque density and durability, making them suitable for heavy-duty applications.

4. Chain Couplings: Offer a simple yet robust solution for connecting shafts in conveyor systems.

5. Disc Couplings: Provide high-performance torque transmission with minimal maintenance requirements.

Selecting the Right Industrial Coupling

Choosing the appropriate industrial coupling for a conveyor belt involves considering several factors:

– Torque Requirements: The coupling must withstand the system’s torque demands.

– Misalignment Tolerance: Depending on the system’s alignment accuracy, a more flexible coupling might be necessary.

– Environmental Conditions: The coupling should be resistant to the operational environment’s conditions, such as temperature, humidity, and exposure to chemicals.

– Maintenance Needs: Opt for couplings that align with the system’s maintenance capabilities and schedules.

Maintaining Your Industrial Coupling

Regular maintenance is crucial for the longevity and efficiency of industrial couplings. This includes:

– Routine Inspections: Regularly check for signs of wear, misalignment, or damage.

– Lubrication: Some couplings require periodic lubrication to operate smoothly.

– Alignment Checks: Ensure the coupling and connected shafts remain properly aligned.

Applications of Industrial Coupling in Conveyor Systems

Industrial couplings are utilized in various conveyor systems, including bulk material handling conveyors, belt conveyors, roller conveyors, and more. Their adaptability and efficiency make them indispensable in industries such as manufacturing, mining, agriculture, and logistics.

Introducing HZPT: Your Industrial Coupling Solution

At HZPT, we pride ourselves on being at the forefront of industrial coupling manufacturing. With an annual output of 15,000 tons of castings, 1.5 million tapered fastening bushings, and 300,000 coupling parts, our production capacity speaks to our capability and dedication to quality.

Why Choose HZPT?

– Professionally Certified: Our products meet international quality standards, ensuring reliability and performance.

– Customized Solutions: We offer tailored coupling solutions to meet unique operational needs.

– Advanced Production Equipment: Our state-of-the-art manufacturing technology ensures high-quality products.

– Comprehensive After-Sales Service: Our commitment to customer satisfaction extends beyond the purchase, with dedicated support and service.

Promotional Slogan

“Connect with Confidence – HZPT Couplings: Engineered for Excellence, Designed for Durability.”

—

—

Note: This condensed version and outline provide a framework for a comprehensive article on industrial couplings for conveyor belts, focusing on their importance, types, selection, maintenance, and applications, with a special emphasis on HZPT’s offerings and capabilities.