Understanding Diaphragm Couplings Vs Disc Coupling: A Comprehensive Guide

When it comes to power transmission, choosing the right coupling is critical. In this guide, we will delve into the details of diaphragm couplings vs disc coupling, shedding light on their design, operation principles, benefits, and selection criteria.

Design and Operational Principles of Diaphragm and Disc Couplings

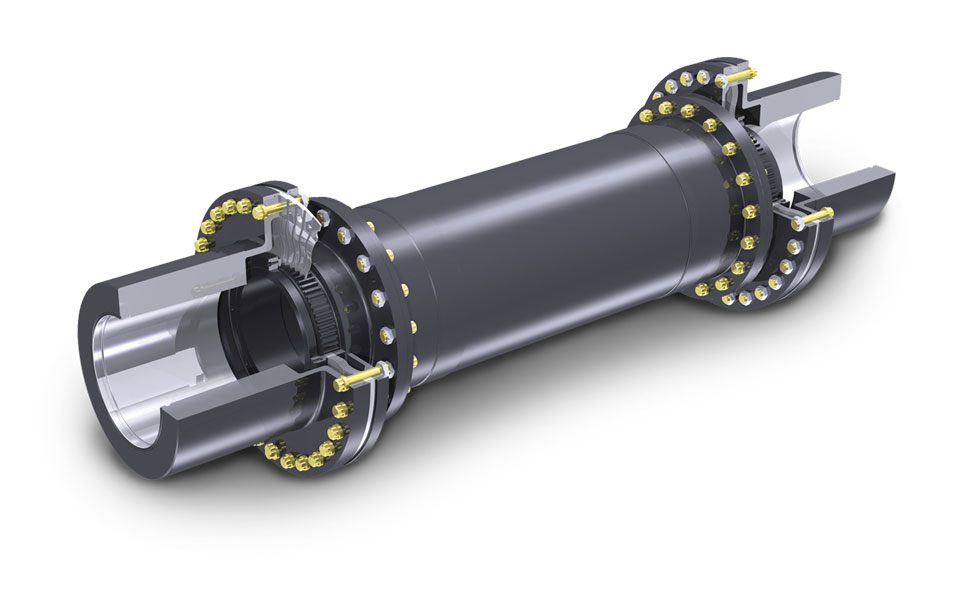

Both diaphragm couplings and disc couplings are designed to connect two shafts while allowing some degree of misalignment. The diaphragm coupling uses a series of thin, flexible plates that can deform slightly under torque, while the disc coupling uses a rigid disc to transmit torque.

Benefits of Diaphragm Couplings

Diaphragm couplings are known for their high torque capacity, excellent misalignment capabilities, and low maintenance. Their flexible nature also reduces the mechanical stress on attached equipment, prolonging their service life.

Selection Criteria for Choosing Couplings

When deciding between diaphragm couplings vs disc coupling, consider factors such as torque requirements, shaft alignment, operating environment, and cost.

Installation and Maintenance of Couplings

Proper installation and maintenance of couplings are crucial to ensure their optimal performance and longevity. This includes regular inspection for wear and tear, lubrication where necessary, and timely replacement of worn-out parts.

About HZPT: Your Trusted Partner in Coupling Manufacturing

HZPT is a manufacturer specializing in the production of couplings. With advanced production and inspection equipment, we produce an annual output of 15,000 tons of castings, 1.5 million tapered fastening bushings, and 300,000 coupling parts. Our efficient and flexible management system, advanced technology, and comprehensive quality control system ensure that our products are of excellent quality and reasonably priced.

Why Choose HZPT?

- Professionalism: We have a team of experienced professionals dedicated to providing the best solutions for your coupling needs.

- International Certification: Our products meet international quality standards, providing assurance of their reliability and durability.

- Customized Services: We offer customized solutions tailored to your specific requirements.

- Advanced Production Equipment: Our state-of-the-art facilities ensure high-quality production.

- Excellent After-Sales Service: We provide comprehensive after-sales service, ensuring customer satisfaction.

“Join hands with HZPT, where quality meets reliability!”