Discover the Power of Diaphragm Couplings for Packaging Machines

Diaphragm couplings for packaging machines are critical components engineered to facilitate reliable power transmission in various packaging operations. These couplings are particularly designed to offer superior flexibility, high torque capacity, and excellent misalignment capabilities, making them an optimal choice for packaging machines.

Design and Operational Principles of Diaphragm Couplings

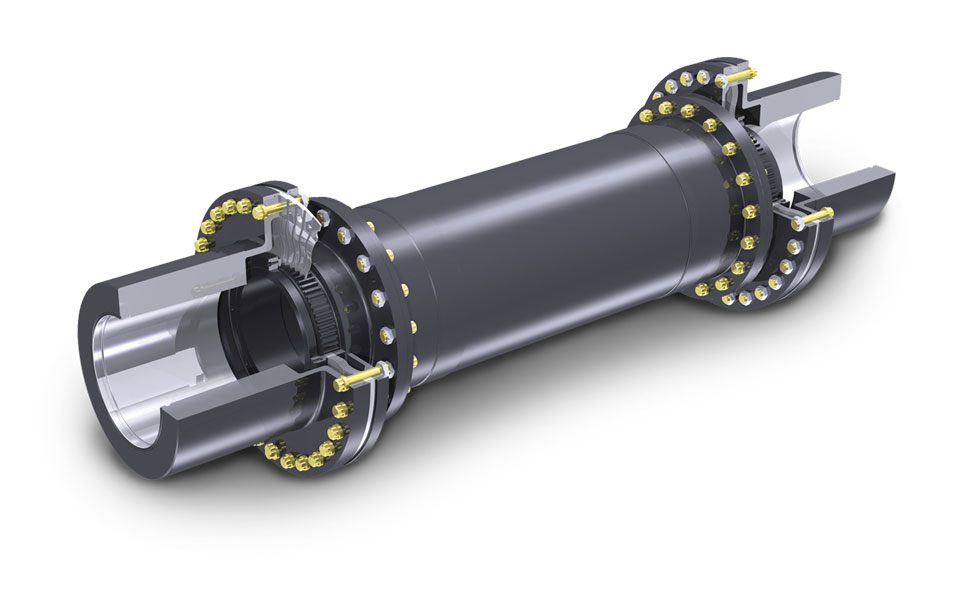

Diaphragm couplings operate on simple mechanical principles. They feature two end fittings, termed as hubs, which are connected through a flexible diaphragm. This diaphragm permits the couplings to accommodate different types of misalignment including angular, axial, and parallel, while transmitting torque effectively.

Benefits and Selection Criteria of Diaphragm Couplings

Diaphragm couplings offer numerous benefits such as high torsional stiffness, zero backlash, and extended operational life. When choosing diaphragm couplings for packaging machines, consider factors such as torque requirements, shaft sizes, speed of operation, and level of misalignment.

Installation and Maintenance of Diaphragm Couplings

Proper installation and maintenance of diaphragm couplings are crucial for optimal performance. Regular inspections and timely replacement of worn-out components can significantly extend the lifespan of these couplings and improve the overall efficiency of your packaging machines.

Introducing HZPT: Your Trusted Manufacturer of Diaphragm Couplings

HZPT is a leading manufacturer specializing in the production of couplings, boasting an annual output of 15,000 tons of castings, 1.5 million tapered fastening bushings, and 300,000 coupling parts. Our efficient and flexible management system, advanced equipment and technology, and stringent quality control system ensure that we provide products of superior quality at reasonable prices.

- Professionalism: With years of experience in the industry, our team possesses the expertise to deliver outstanding products and services.

- International Certification: Our products meet international standards for quality and safety, ensuring peace of mind for our customers.

- Customized Services: We provide customized solutions to meet the unique needs of each customer.

- Advanced Equipment: Our state-of-the-art production and inspection equipment enable us to produce high-quality products consistently.

- After-Sales Service: We offer comprehensive after-sales service to ensure customer satisfaction.

Your Success, Our Commitment. Choose HZPT for Quality Diaphragm Couplings for Packaging Machines!