新品未使用未開封 NEC PA-WX5400HP Wi-Fi 6

(税込) 送料込み

商品の説明

新品未使用未開封

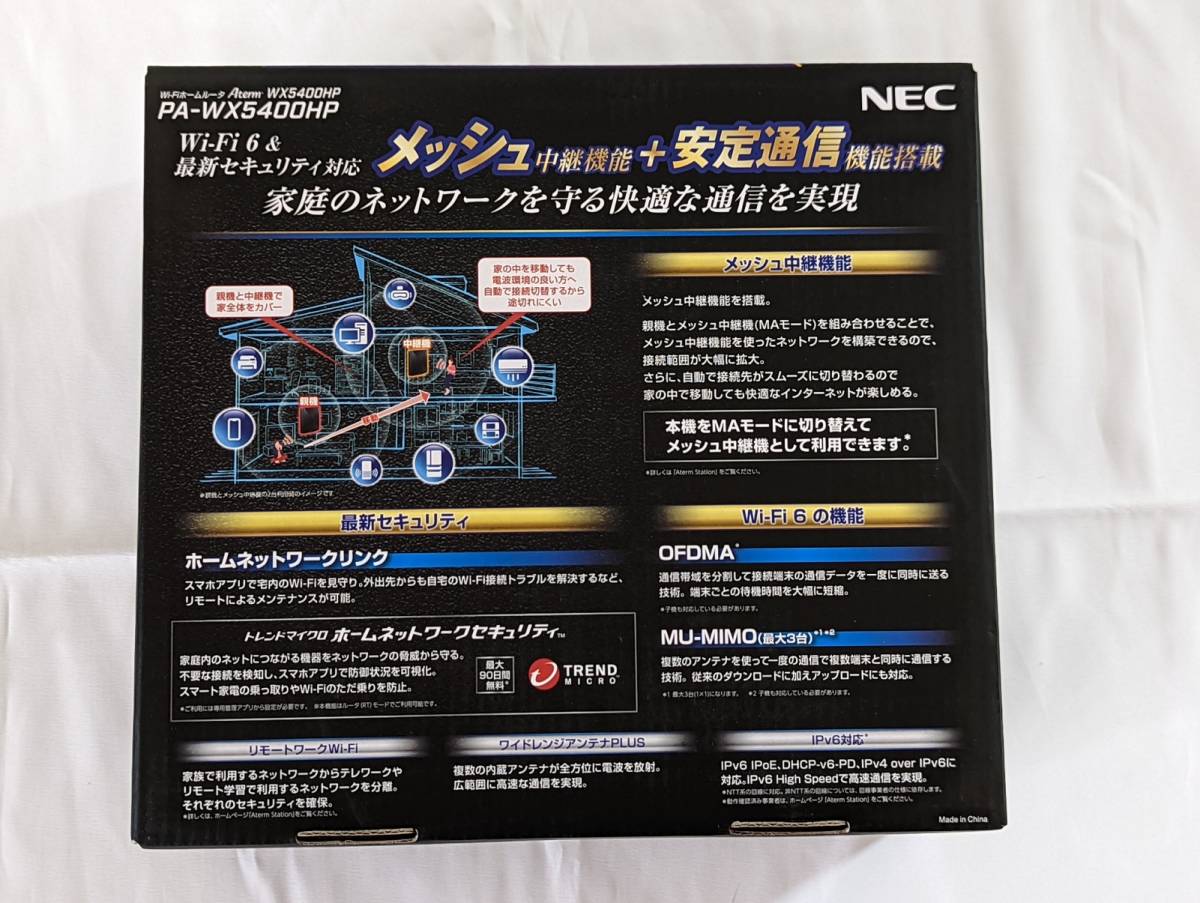

NEC Aterm PA-WX5400HP Wi-Fi 6(11ax)対応 IPV6 ハイスピード 無線LANルーター

【Aterm®︎ Station 製品情報ページ】

/product/atermstation/product/warpstar/wx5400hp/

のご紹介です。

2022年9月に購入しました。

Wi-Fi6e対応のルターを購入する予定なので

必要なくなったので出品いたします。

箱に入れて保管していました。

神経質な方はご遠慮下さい。簡易包装にて発送いたします。質問等ありましたら、遠慮なくコメント欄でお願いいたします。返信は遅くなるかもしれませんが 対応させて頂きます。コメントなくても、即購入OKです。交渉中であっても先に購入された方を優先します。よろしくお願いいたします。商品の情報

| カテゴリー | スマホ・タブレット・パソコン > PC周辺機器 > ルーター・ネットワーク機器 |

|---|---|

| 商品の状態 | 新品、未使用 |

NEC Wi-Fi PA-WX5400HP無線LANメッシュ対応 新品 未開封品-

NEC Wi-Fi ルーター Aterm PA-WX5400HP 新品未使用-

NEC Wi-Fi PA-WX5400HP無線LANメッシュ対応 新品 未開封品-

NEC Wi-Fi ルーター Aterm PA-WX5400HP 新品未使用-

未使用品】NEC PA-WX5400HP-

特注加工 【新品未開封】NEC PA-WX5400HP BLACK | www.chudotv.bg

新品・未開封】NEC PA-WX5400HP Aterm WX5400HP|代購幫

未使用品】Wi-Fiルーター NEC Aterm PA-WX5400HP-

NEC Wi-Fi PA-WX5400HP無線LANメッシュ対応 新品 未開封品-

未使用品】NEC PA-WX5400HP-

未使用品】Wi-Fiルーター NEC Aterm PA-WX5400HP-

新品未開封】Wi-Fi 無線LANルーター WX5400HP-

NEC Wi-Fi PA-WX5400HP無線LANメッシュ対応 新品 未開封品-

NEC Aterm WX5400HP PA-WX5400HP オークション比較 - 価格.com

NEC Wi-Fi PA-WX5400HP無線LANメッシュ対応 新品 未開封品-

未使用品】Wi-Fiルーター NEC Aterm PA-WX5400HP-

送料無料 新品未開封 2台セット NEC Aterm WX5400HP PA-WX5400HP 無線

ウェッブ宇宙望遠鏡 NEC 無線 ルータ PA-WX5400HP ブラック Wi-Fi 無線

NEC Wi-Fiルーター Aterm PA-WX5400HP WiFi6対応 の入札履歴 - 入札者

新品未使用品。WiFiルーター!NEC PA-WX5400HP BLACK+inforsante.fr

新品:納品書付】NEC 無線LANルーター PA-WX5400HP-

未開封新品】Wi-Fi ホームルータ PA-WX5400HP - メルカリ

☆新品未開封 4台セット! NEC Wi-Fiルーター Aterm PA-WX5400HP WiFi6

匿名配送〉NEC PA-WX5400HP BLACK-

◇新品未開封 2台セット! NEC Wi-Fiルーター Aterm PA-WX5400HP WiFi6

NEC PA-WX5400HP BLACK-

Aterm WX5400HP PA-WX5400HP - その他

NEC Wi-Fi ルーター Aterm PA-WX5400HP 新品未使用-

WIFI 6 ルーター NEC Aterm WX5400HP 交換無料 64.0%OFF weekend.fm

未開封新品】Wi-Fi ホームルータ WX5400HP-

2024年最新】WX5400HPの人気アイテム - メルカリ

新品未使用品。WiFiルーター!NEC PA-WX5400HP BLACK+inforsante.fr

NEC - 【新品未使用】NEC 無線ルータ ブラック PA-WX5400HPの通販 by

◇新品未開封 2台セット! NEC Wi-Fiルーター Aterm PA-WX5400HP WiFi6

NEC Wi-Fi ルーター Aterm PA-WX5400HP 新品未使用-

新品:納品書付】NEC 無線LANルーター PA-WX5400HP-

2024年最新】Yahoo!オークション -pa-wx5400hpの中古品・新品・未使用

NEC エヌイーシ Wi-Fiルーター Aterm(エーターム) PA-WX5400HP - メルカリ

☆新品未開封 NEC Wi-Fiルーター Aterm PA-WX5400HP WiFi6対応 ※送料

新品未使用品。WiFiルーター!NEC PA-WX5400HP BLACK+inforsante.fr

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています