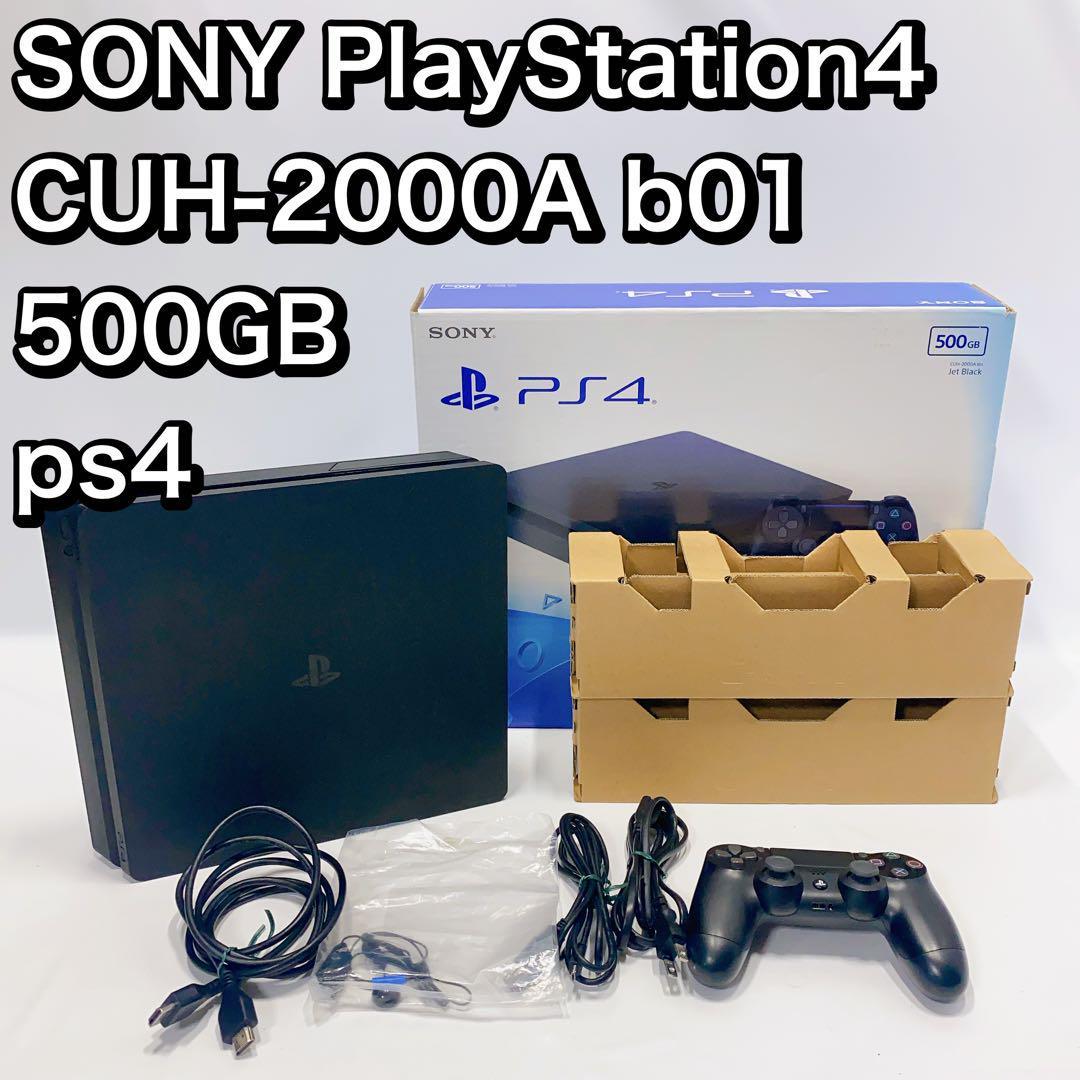

PS4 本体 CUH-2000A BO1

(税込) 送料込み

商品の説明

PS5購入に伴い出品致します。

・ブランド

ーSONY

・サイズ

ー500GB

・カラー

ーJet Black

・型CUH-2000A B01

内容物(完品、全て動作確認済みです)

・PS4本体

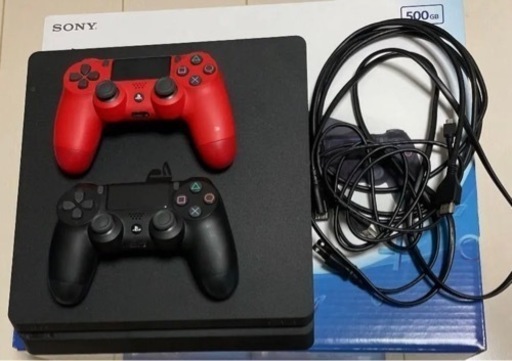

・ワイヤレスコントローラー

・モノラルヘッドヘッド(未使用)

・電源コード

・HDMI(R)ケーブル

・USBケーブル

コントローラー裏面のシールが剥がれていますが動作問題ありません。

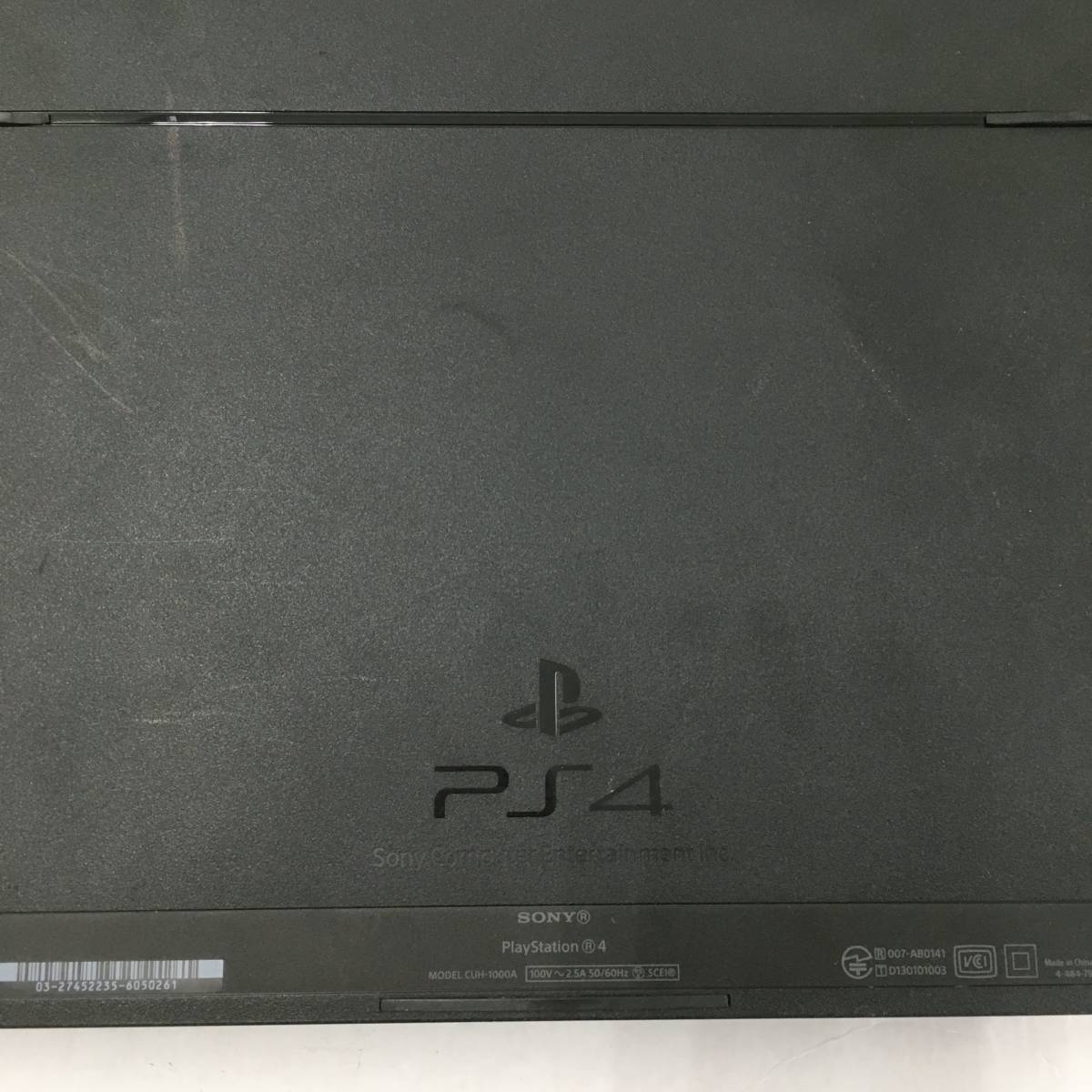

本体は初期化、消毒済み、バージョンは現在の最新版(ver.11.02)にアップデートしてあります。

素人保管ですのでご理解頂ける方のみよろしくお願い致します。

値引き、返品不可でお願い致します。商品の情報

| カテゴリー | ゲーム・おもちゃ・グッズ > テレビゲーム > Nintendo Switch |

|---|---|

| ブランド | ソニー |

| 商品の状態 | やや傷や汚れあり |

ps4 CUH-2000A BO1 500GBエンタメ/ホビー - www.primator.cz

PS4 本体u3000500GB CUH-2000A BO1 ジェットブラック 一番ちょうどいい

SONY PS4 CUH-2200A BO1 Jet Black 500GB本体 - 家庭用ゲーム本体

貴重 PlayStation4ジェットブラック 500GB CUH-2000A BO1 - テレビゲーム

PS4 本体u3000500GB CUH-2000A BO1 ジェットブラック 一番ちょうどいい

PS4 本体 CUH-2000A Jet Black 500GB-

大好き PlayStation®4 500GB CUH-2000A BO1 | portal.cesist.cl

PS4 本体 CUH-2000A Jet Black 500GB-

PS4 本体 CUH-2000A 500G-

PS4 CUH-2000A BO1 ジェットブラック 500GB プレイステーション4

PlayStation4 本体 CUH-2000A B01 500GB PS4-

PS4 CUH-2000A 500G - esolar.ba

新型 PS4 本体 CUH-2000A BO1 Jet Blackの+vprogress.com.au

PS4 本体 CUH-2000A Jet Black 500GB-

PS4 本体u3000500GB CUH-2000A BO1 ジェットブラック 一番ちょうどいい

PlayStation4 - ps4 CUH-2000A BO1 500GBの+inforsante.fr

お取り寄商品 playstation 4本体 CUH-2000A BO1 500GB - delfingroup.eu

PlayStation4 - ps4 CUH-2000A BO1 500GBの+inforsante.fr

新型 PS4 本体 CUH-2000A BO1 Jet Blackの+vprogress.com.au

PS4 本体u3000500GB CUH-2000A BO1 ジェットブラック 一番ちょうどいい

PS4 プレステ4 本体CUH-2000A⭐︎PS4後期薄型です!動作OKです

PS4 CUH-1000A BO1 500GB-

Amazon.co.jp: PS4 本体 CUH-2000A BO1 500GB

SIE プレイステーション4 HDD 500GB ジェット・ブラック CUH-2000AB01

PS4 本体 CUH-2000A Jet Black 500GB-

PlayStation4 プレステ4 ジェットブラック PS4 PS4本体 CUH-2000A Bo1

新型 PS4 本体 CUH-2000A BO1 Jet Blackの+vprogress.com.au

PlayStation4 - プレイステーション4 PS4 CUH-2000A BO1の+

Amazon.co.jp: PS4 本体 CUH-2000A BO1 500GB

PS4 本体u3000500GB CUH-2000A BO1 ジェットブラック 一番ちょうどいい

PlayStation4 - ps4 CUH-2000A BO1 500GBの+inforsante.fr

PlayStation®4 ジェット・ブラック 500GB CUH-2000A…-

2024年最新】ps4 cuh-11 a boの人気アイテム - メルカリ

豪華で新しい その他 SONY PS4 CUH-2000A BO1 JET BLACK その他

2024年最新】ps4 cuh-2000の人気アイテム - メルカリ

PS4 本体u3000500GB CUH-2000A BO1 ジェットブラック 一番ちょうどいい

PlayStation4 - プレイステーション4 PS4 CUH-2000A BO1の+

トップゲーム・アニメ PlayStation®4 ジェット・ブラック 500GB CUH

大好き PlayStation®4 500GB CUH-2000A BO1 | portal.cesist.cl

新型 PS4 本体 CUH-2000A BO1 Jet Blackの+vprogress.com.au

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています