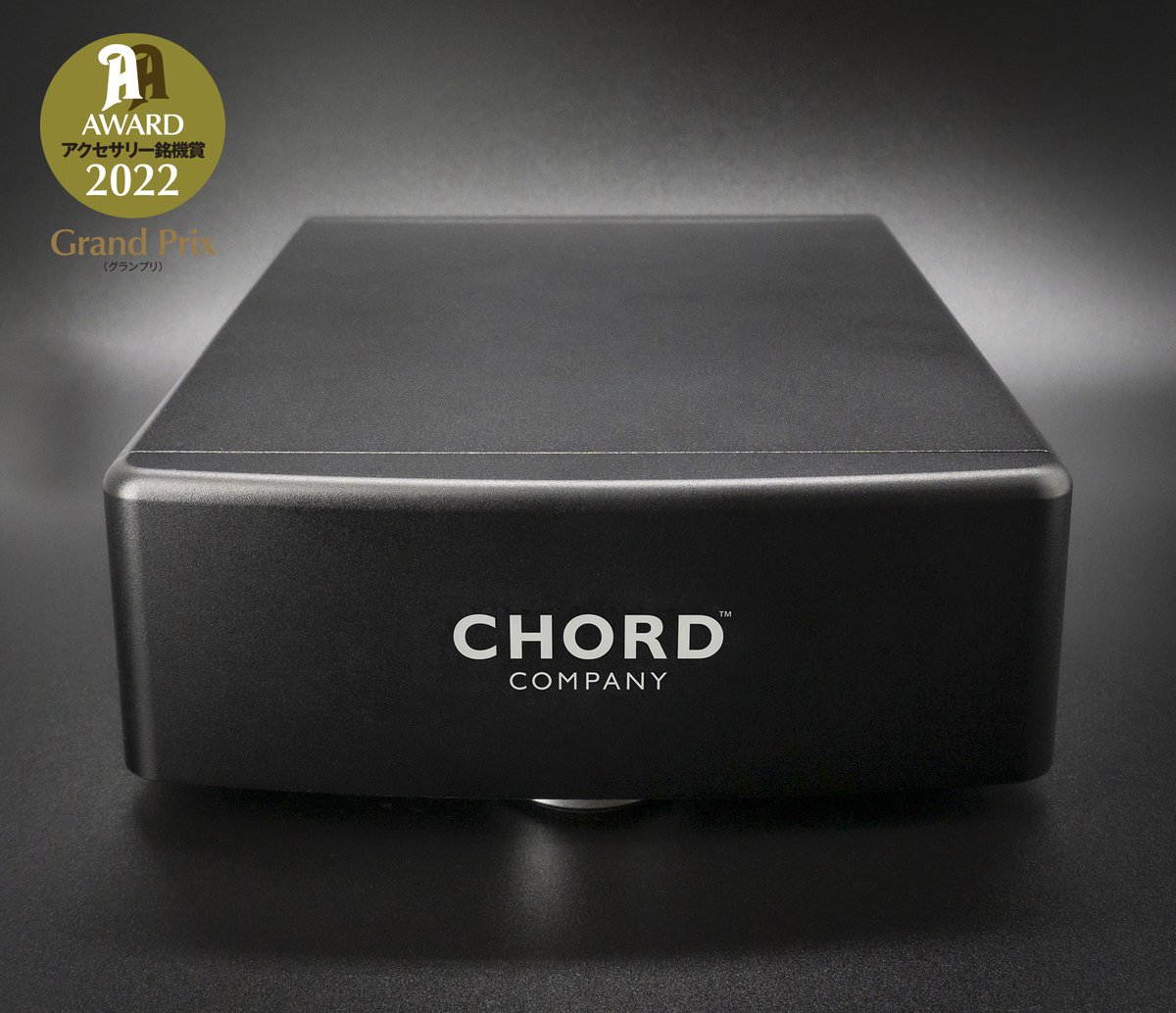

CHORD COMPANY PowerARAY コードカンパニー電源プラグ

(税込) 送料込み

商品の説明

CHORD COMPANYPowerARAY

コードカンパニーパワーアレイ

ノイズポンプ。

汚れ小キズあります。

中古品なので神経質な方はご遠慮下さい。商品の情報

| カテゴリー | テレビ・オーディオ・カメラ > オーディオ機器 > その他 |

|---|---|

| 商品の状態 | やや傷や汚れあり |

ノイズポンププラグ 3P PowerARAY-3P

PowerARAY Professional | アンダンテラルゴ株式会社

THE CHORD COMPANY (コードカンパニー) 高周波ノイズ対策プラグ PowerAray ブレード3ピンタイプ 1本 : poweraray : オーディオユニオン909 - 通販 - Yahoo!ショッピング

ノイズポンププラグ 2ピン CHORD COMPANY PowerARAY-2P

PowerARAY Professional | アンダンテラルゴ株式会社

CHORD COMPANY PowerARAY コードカンパニー電源プラグ - その他

SALE55%OFF CHORD COMPANY PowerARAY コードカンパニー電源プラグ

PowerARAY Professional

メーカー直送> PowerARAY Professional(標準モデル/80cmの「シグネ...

PowerARAY Professional | アンダンテラルゴ株式会社

CHORD COMPANYPowerARAY コードカンパニー電源プラグ-

CHORD COMPANY コードカンパニー Power ARAY ノイズポンププラグ

The Power ARAY Effect | The Ear

SALE55%OFF CHORD COMPANY PowerARAY コードカンパニー電源プラグ

ノイズポンプ・パワーアレイ3Pタイプ(1個) | Joshin webショップ

CHORD COMPANY コードカンパニー Power ARAY ノイズポンププラグ

PowerARAY Professional

CHORD COMPANY コードカンパニー Power ARAY ノイズポンププラグ

PowerARAY | アンダンテラルゴ株式会社

THE CHORD COMPANY (コードカンパニー) 高周波ノイズ対策プラグ

PowerARAY | アンダンテラルゴ株式会社

ノイズポンプ・パワーアレイ3Pタイプ(1個) | Joshin webショップ

ノイズポンプ・パワーアレイ3Pタイプ(1個) | Joshin webショップ

ノイズポンプ・パワーアレイ3Pタイプ(1個) | Joshin webショップ

PowerARAY | アンダンテラルゴ株式会社

THE CHORD COMPANY : PowerARAY(3ピンタイプ) - 中古 | オーディオ

The Power ARAY Effect | The Ear

CHORD COMPANYPowerARAY コードカンパニー電源プラグ-

ノイズポンプ・パワーアレイ3Pタイプ(1個) | Joshin webショップ

CHORD COMPANY PowerARAY /1個 ノイズ吸収プラグ 【お取り寄せ】- 音質

CHORD COMPANY PowerARAY – DynamicAudio 5555 H.A.L.3

CHORD COMPANY PowerARAY コードカンパニー電源プラグ-

CHORD COMPANY PowerARAY Professional 体験展示~7月31日マデ

ノイズポンプ・パワーアレイ3Pタイプ(1個) | Joshin webショップ

コード・カンパニーの最新兵器。「パワーアレイ・プロフェッショナル

CHORD COMPANY PowerARAY Professional 体験展示~7月31日マデ

PowerARAY | アンダンテラルゴ株式会社

THE CHORD COMPANY : PowerARAY(3ピンタイプ) - 中古 | オーディオ

パワーアレイの集大成「PowerARAY Professional」を試してみた

電源用ノイズポンププラグ PowerARAY ( 3ピンタイプ) | オーディオ

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています