SONY UWP-D21 ワイヤレスピンマイク

(税込) 送料込み

商品の説明

SONY(ソニー) B帯アナログワイヤレスマイクロホンパッケージ UWP-D21//KBJ

製品型番UWP-D21

YouTube用で購入しましたが、何度か使用してyoutubeをやめてから放置しました。

お探しの方どうぞよろしくお願いします。商品の情報

| カテゴリー | テレビ・オーディオ・カメラ > オーディオ機器 > その他 |

|---|---|

| 商品の状態 | 目立った傷や汚れなし |

UWP-D21 | プロオーディオ | ソニー

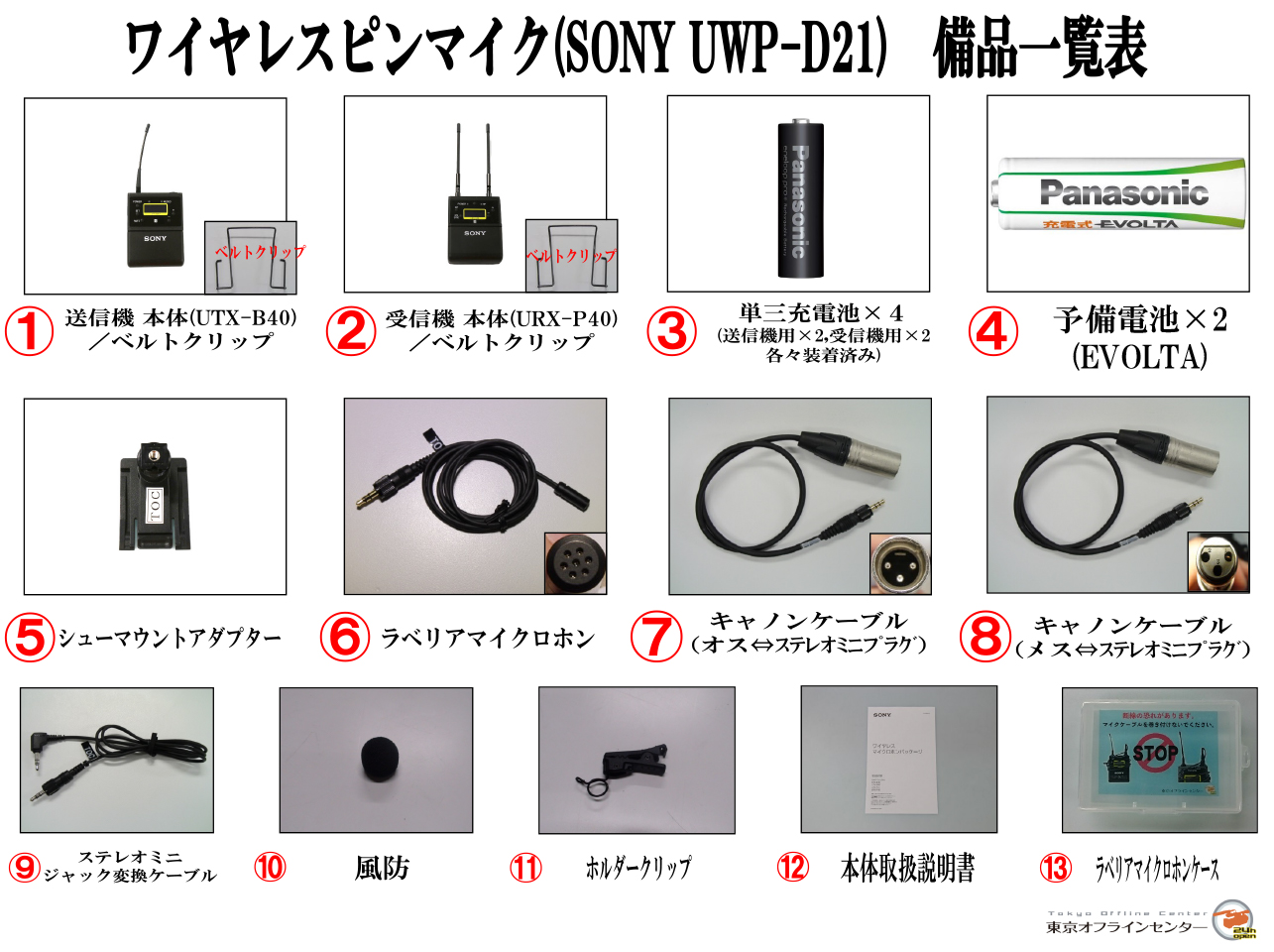

SONY UWP-D21|デジタイズから機材レンタルなどオフライン編集の総合

UWP-D21レンタル | 業務用ワイヤレスマイクロホンパッケージ

SONY UWP-D21|デジタイズから機材レンタルなどオフライン編集の総合

機材名| 撮影レンタル機材 | TFC Plus Corporation

SONY UWP-D21 B帯アナログワイヤレスマイクロホンパッケージ(ボディー

先日の配信では、ワイヤレスピンマイクUWP-D21の優秀さを感じた|松井

2.3回使用】SONY UWP-D21 ワイヤレスマイク+シューSMAD-P5-

高評価 SONY UWP-D21 ワイヤレスマイク | www.prosense.com.br

SONY UWP-D21 ワイヤレスマイク エネループ10本おまけ ソニー ホビー

SONY - 【新品】SONY ワイヤレスマイク UWP-D21の通販 by たむ's shop

【新製品】ソニーのワイヤレスマイクシステムUWP-D21を従来モデルD11と比較してみた!

SONYの新型ワイヤレスマイクセット】UWP-D21、登場! - YouTube

SONY UWP-D21 ワイヤレスマイク エネループ10本おまけ ソニー ホビー

SONY UWP-D21 ワイヤレスマイク エネループ10本おまけ ソニー ホビー

UWP-D21 ワイヤレスピンマイク ウインドスクリーン付-

比較検索 SONY UWP-D21 ワイヤレスマイク - 楽器/器材

SONY UWP-D21 ワイヤレスマイク ソニー オンラインストア純正

SONY UWP-D21 B帯アナログワイヤレスマイクロホンパッケージ(ボディー

ソニー SONY UWP-C1 ワイヤレスマイク-

SONY UWP-D21 ワイヤレスマイク エネループ10本おまけ ソニー ホビー

特別価格 ワイヤレスマイクロホンパッケージ UWP-D21//KBJ UWP-D UWP

2台セット SONY B帯 ワイヤレスマイク UWP-D21-

10分で分かる! ワイヤレスピンマイクの使い方【準備編】使用マイク: SONY UWP-D11

ワイヤレスマイクロホンパッケージ UWP-D 21(ピンマイク)-

UWP-D11 | プロオーディオ | ソニー

が購入できます SONY UWP-D21 B帯アナログワイヤレスマイクロホン

Amazon.co.jp: ワイヤレスマイクロホン SONY UWPシリーズ用 プロ 撮影

ソニーワイヤレスピンマイク SONY UWP-D21 / SMAD-P5 開封レビュー【a7iiで使ってみる】

意外と簡単!SONY UWPシリーズを使ってみました! - 東京カメラ機材

![SONY UWP-D21 [B帯アナログワイヤレスマイクロホンパッケージ] 中古](https://www.fujiya-camera.co.jp/img/goods/2/C2120127561708_2.jpg)

SONY UWP-D21 [B帯アナログワイヤレスマイクロホンパッケージ] 中古

動画あり】新製品UWP-D21を旧モデルと比べてみました(使い勝手

SONY UWP-D21 B帯アナログワイヤレスマイクロホンパッケージ(ボディー

UWP-D21】 SONY B帯アナログワイヤレスマイクロホンパッケージ-

SONY UWP-D21 ワイヤレスマイク - その他

2024年最新】sony uwp-d21の人気アイテム - メルカリ

オーディオ/コミュニケーション | ワイヤレスマイク | UWP-D21 | 商品

2024年最新】SONY UWP-D21の人気アイテム - メルカリ

Amazon | NiceAI ラベリアマイク SONY UWPシリーズ用 ワイヤレス

ネット予約 |東京オフラインセンター

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています