超合金魂 GX-33R レオパルドン&マーベラー召喚セット 「スパイダーマン」

(税込) 送料込み

商品の説明

ご覧いただき誠にありがとうございます。

商品は、

「超合金魂 GX-33R レオパルドン&マーベラー召喚セット 「スパイダーマン」」

です。

過去に購入後、暗所にて保存しておりました。

購入時にテープが2度張りされていたため、出品にあたり念のため開封しました。

開封、未使用品です。

商品は写真のもので全てです。

以下状態です。

・外箱

一ヶ所、表面の右上(MARVELロゴの左下あたり)に触ると分かる程度の凹みがあります。

また、箱の側面に若干の痛みがあります。(写真10)

全体としては結構きれいだと思いますが、完全美品ではなく、あくまで中古品としてになります。写真もご確認下さい。

(その他、微細なキズ、スレはあるものとお考えください。)

・商品本体

開封、未使用です。特に痛みや変色は見られません。

(写真でご判断下さいませ。)

・説明書

未開封です。多少の曲がりはあります。

以上、素人検品ですので多少の見落としはご容赦下さい。

あくまで中古品であることをご理解の上、ご購入下さい。

本商品は未使用の為、すり替え防止の為、ncnrでお願いします。

即購入可です。

水濡れ対策をしてプチプチで包み、別の段ボールで宅急便にて発送します。

プロフもご参照下さい。

【商品解説】

スパイダーマンとなって、マーベラーを召喚せよ!叫べ!マーベラー!

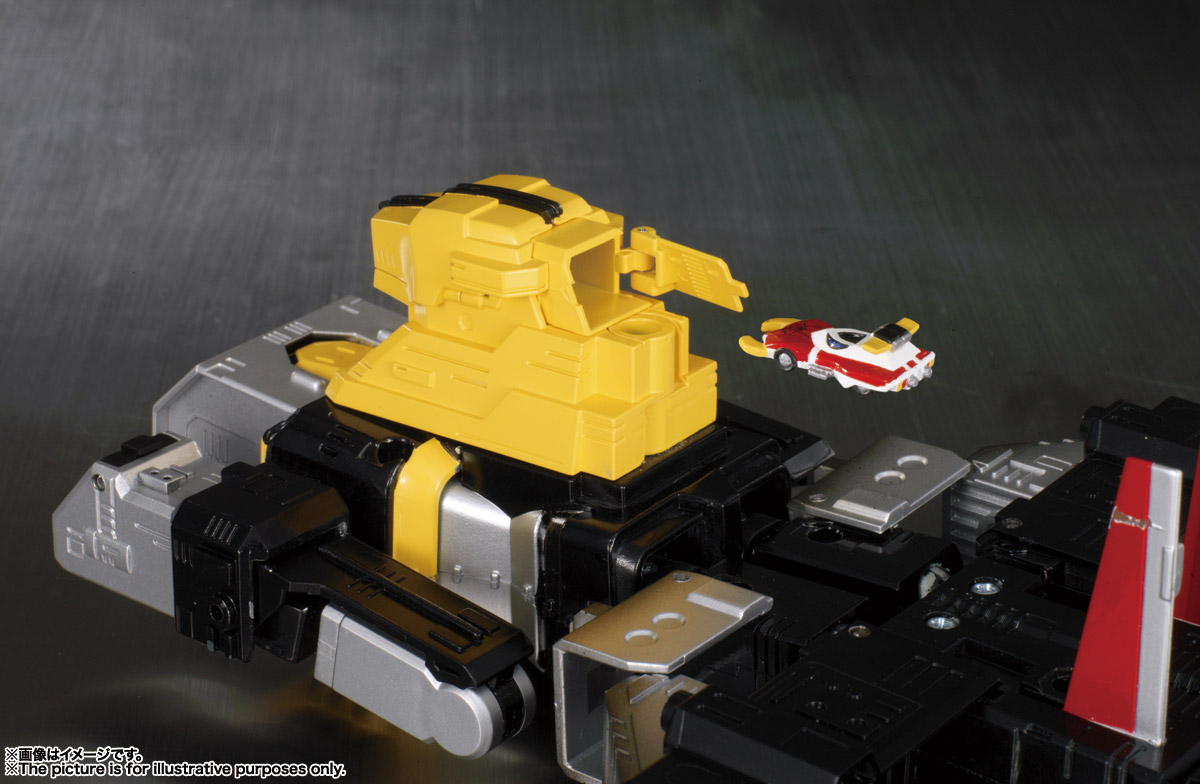

「スパイダーマン」東映テレビシリーズより巨大ロボットレオパルドンが超合金魂に再登場。

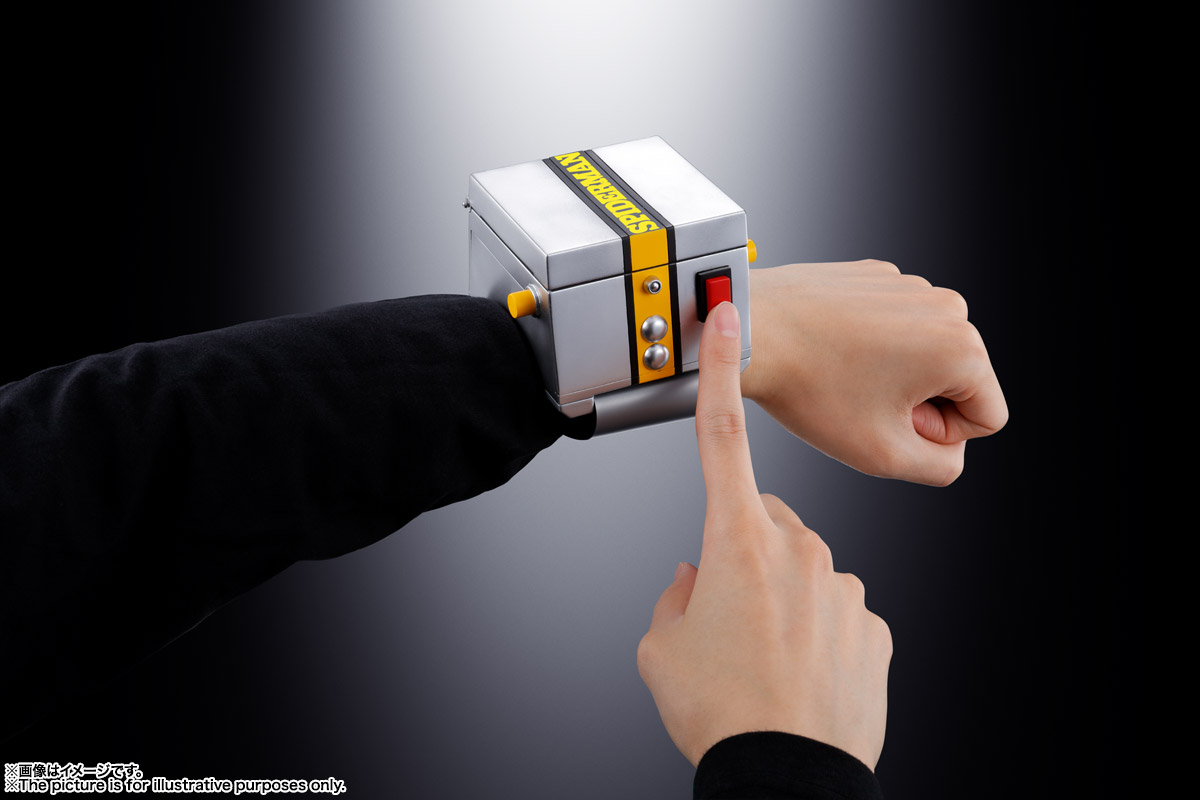

今回はスパイダーブレスレットが楽曲&音声機能付きで初立体化。変形前の宇宙戦闘艦マーベラーを召喚せよ!

放映当時にも商品化の無かった、スパイダーブレスレットが遂に登場。

手首への装着が可能。

スパイダーマンのミニフィギュアと同スケールのダイキャスト製の「スパイダーマシンGP-7」が付属。

(レオパルドンに収納できる小型の「スパイダーマシンGP-7」も付属)

【商品詳細】

サイズ:全高約170mm(レオパルドン時)

使用電池:単4乾電池×2(別売り)

#BANDAI

#SPIDER-MAN

#MARVEL

#マーベル

#東映

#超合金魂

#レア

#希少

#未使用

#新品

フィギュア種類...アクションフィギュア

素材...ABS

スケール...ノンスケール商品の情報

| カテゴリー | ゲーム・おもちゃ・グッズ > フィギュア > コミック・アニメ |

|---|---|

| 商品の状態 | 未使用に近い |

超合金魂 GX-33R レオパルドン&マーベラー召喚セット 約170mm ダイキャスト・ABS・PVC製 塗装済み可動フィギュア

レビュー「超合金魂 GX-33R レオパルドン&マーベラー召喚セット

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

東映スパイダーマン「超合金魂 GX-33R レオパルドン&マーベラー召喚

超合金魂 GX-33R レオパルドン&マーベラー召喚セット 約170mm ダイキャスト・ABS・PVC製 塗装済み可動フィギュア

超合金魂 GX-33R レオパルドン&マーベラー召喚セットのレオパルドン

Amazon.co.jp: 超合金魂 GX-33R レオパルドン&マーベラー召喚セット 約

超合金魂 GX-33R レオパルドン&マーベラー召喚セット

超合金魂 GX-33R レオパルドン&マーベラー召喚セット

Amazon.co.jp: 超合金魂 GX-33R レオパルドン&マーベラー召喚セット 約

定番のお歳暮&冬ギフト 超合金魂 GX-33R レオパルドン&マーベラ 召喚

公式サイ 超合金魂 GX-33R レオパルドン&マーベラー召喚セット

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

セール開催中 【中古】超合金魂 GX-33R レオパルドン&マーベラー召喚

超合金魂 GX-33R レオパルドン&マーベラー召喚セットのレオパルドン

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

バンダイ 超合金魂 GX-33R レオパルドン&マーベラー召喚セット

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

Amazon.co.jp: 超合金魂 GX-33 レオパルドン&スパイダーマン : ホビー

超合金魂 GX-33R レオパルドン&マーベラー召喚セット バンダイ

おもちゃ:超合金魂 GX-33R レオパルドン&マーベラー召喚セット

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

バンダイ/超合金魂 GX-33R レオパルドン & マーベラー召喚セット/東映

2024年最新】レオパルドン 超合金の人気アイテム - メルカリ

メール便無料 東映版スパイダーマン」レオパルドン、フィギュア“超合金

超合金魂GX- 33Rレオパルドン-

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | 魂ウェブ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット (バンダイ

超合金魂 GX-33R レオパルドン&マーベラー召喚セット | トイ

東映スパイダーマン「超合金魂 GX-33R レオパルドン&マーベラー召喚

【Spider-Man(TOEI ver. )】Soul of Chogokin GX-33R Leopardon & Marveller Summon Set wotafa's review

超合金魂 GX-33R レオパルドン&マーベラー召喚セット(スパイダーマン

レビュー「超合金魂 GX-33R レオパルドン&マーベラー召喚セット

超合金魂 GX-33R レオパルドン&マーベラー召喚セット(スパイダーマン

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています